On November 12, the 5th webinar on Future Skills & AI within the thematic focus Work 5.0 took place. The event was organized by Plattform Industrie 4.0 as part of the Interreg AT-SK project “Twin City Future Innovation Manufacturing Hub.”

Input by Benjamin Schwärzler, Workheld – Use Case: Swiss Post

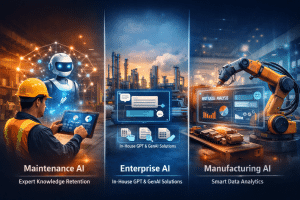

Workheld, a Vienna-based software company specializing in production and maintenance processes, presented an AI-driven use case developed in collaboration with Swiss Post to sustainably preserve critical expert knowledge. The starting point was a key challenge: experienced maintenance experts responsible for sorting systems are approaching retirement, while their know-how is essential for ensuring 24/7 system availability.

Together with Swiss Post, an AI solution was developed that digitally captures this company-specific expert knowledge and makes it available to approximately 300 maintenance technicians at all times. To achieve this, existing data sources—such as incident logs from the expert hotline, SAP data, historical maintenance orders, and manufacturer documentation—were structured, interconnected, and consolidated into a knowledge graph.

The result is a digital second-level support system that secures critical know-how in the long term, supports technicians directly in their daily work, and ensures the continued high availability of Swiss Post’s systems. An additional key feature is multilingual support: in its final expansion stage, the AI solution will be available in German, French, and Italian, reflecting Switzerland’s multilingual environment and making documentation and expertise accessible regardless of the original language.

Input by Philipp Bousa, OMV Group

The presentation provided insights into OMV’s structured approach to establishing and scaling Generative AI across the organization over the past two and a half years. The strategy focused on first developing broadly applicable, standardized AI use cases and then gradually evolving them into highly specialized, high-impact applications.

This approach is built on a clearly defined governance and framework model, emphasizing Responsible AI, information security, data governance, technology partnerships, and platform strategy. Early use cases—such as an in-house GPT and sentiment analysis for multilingual evaluation of IT and employee feedback—were implemented quickly and successfully scaled to additional areas such as HR and retail.

In parallel, OMV invested heavily in employee empowerment through training sessions, workshops, prompting courses, and show-and-tell formats, enabling business units to develop their own AI ideas and apply GenAI effectively in daily work.

Today, OMV operates with reusable GenAI building blocks—including translation, document analysis, RAG, and summarization—delivered via a centralized AI hub. This modular approach enables the implementation of increasingly complex use cases, up to agentic AI solutions, creating sustainable value across the organization.

Input by Markus Wagner, Josef Ressel Center Industrial Data Lab, FH St. Pölten

The Josef Ressel Center “Knowledge Visual Analytics for Industrial Manufacturing Data” focuses on preserving expert knowledge in industry, enabling effective use of large and fragmented data sets, and reducing cognitive overload for employees. The overarching goal is to optimize production processes, reduce setup times, and enhance quality assurance.

The approach is based on Knowledge-Assisted Visual Analytics, where expert knowledge is digitized, stored in knowledge graphs, and combined with causal models to enable targeted analysis of machine and process issues. A key element is the human-in-the-loop, ensuring continuous validation and feedback to prevent model degradation. The insights gained support improved planning and manufacturing processes as well as higher product quality.

Three core use cases were presented:

- Optimization of machine settings

- Sales and Operations Planning

- Root cause analysis (fault detection)

In addition, several prototypes for visual analytics in production, material flow, and logistics were introduced. These solutions combine AI-supported analysis, chatbot-based interaction, and prioritization based on economic impact. The overall objective is to make industrial processes more efficient, safeguard knowledge, and provide cross-industry guidelines based on the research outcomes.

Many thanks to the speakers for their inspiring insights!